Development trends in production of packaging

what glass is and how it is used;

what cellulose is, what its properties are and where it can be found;

what corrosion is.

to describe how directions of packaging materials development were shaped;

to list factors that are taken into account when choosing packaging material;

to discuss selected applications along with disadvantages and advantages of different packaging (cellulose, glass, metal, artificial) used on a daily basis;

to divide plastics into polymerization and polycondensation ones.

The impact of changing conditions in business life on the packaging development

Virtually every product available on the market has a characteristic packagingpackaging. The packaging industry is a dynamically developing sector, subject to constant changes. In this case, the production volume has a close relationship with the civilization development of given country. Not only producers and users are interested in market situation. It is also the matter of interest of economists, ecologists and artists. Self‑service sales, online shopping, customer preferences, environmental protection requirements and high competition on the market mean that today the packaging is not only an addition to the product, but often it itself is a product.

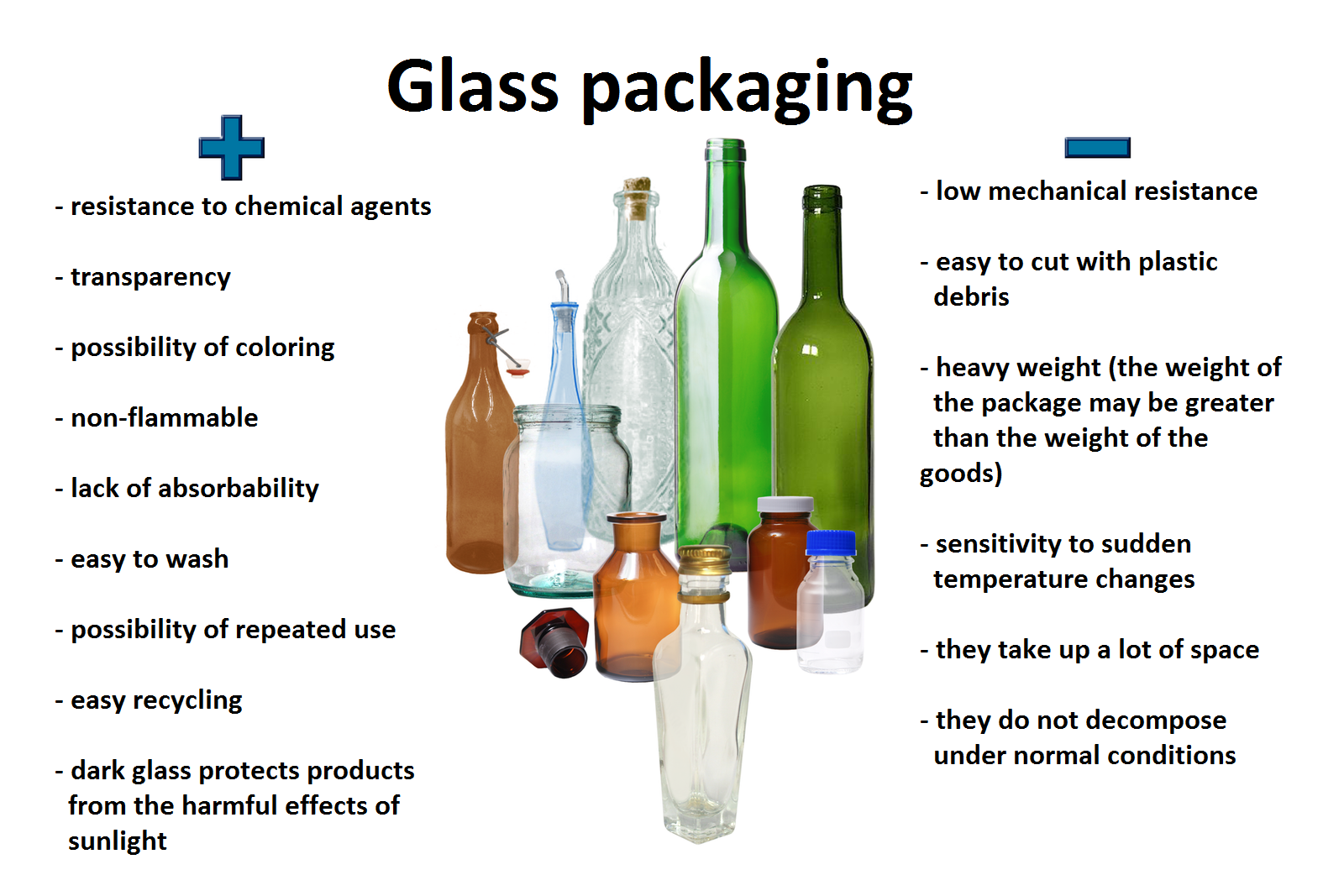

Glass packaging

The oldest glass containers – amphorae and vases discovered by archaeologists – are over 3500 old. Bottles were a luxury commodity until a man learned how to make glass objects using glass shafts. However, it was the mastering of the art of glass casting that popularized the use of packaging from this material. Being produced from natural raw materials: sand, soda and limestone – glass is the most environment‑friendly material used to pack food, beverages, pharmaceutical products and cosmetics. Packaging with very sophisticated shapes and colours can be created as it is very easy to form and dye the glass mass. Glass packaging do not react with products that are stored in them, their transparency allows the consumer to assess the quality of the product, and dark colour protects some products from light. Owing to the possibility of being re‑used and easy recycling glass is an environment‑friendly material although it is not free of defects.

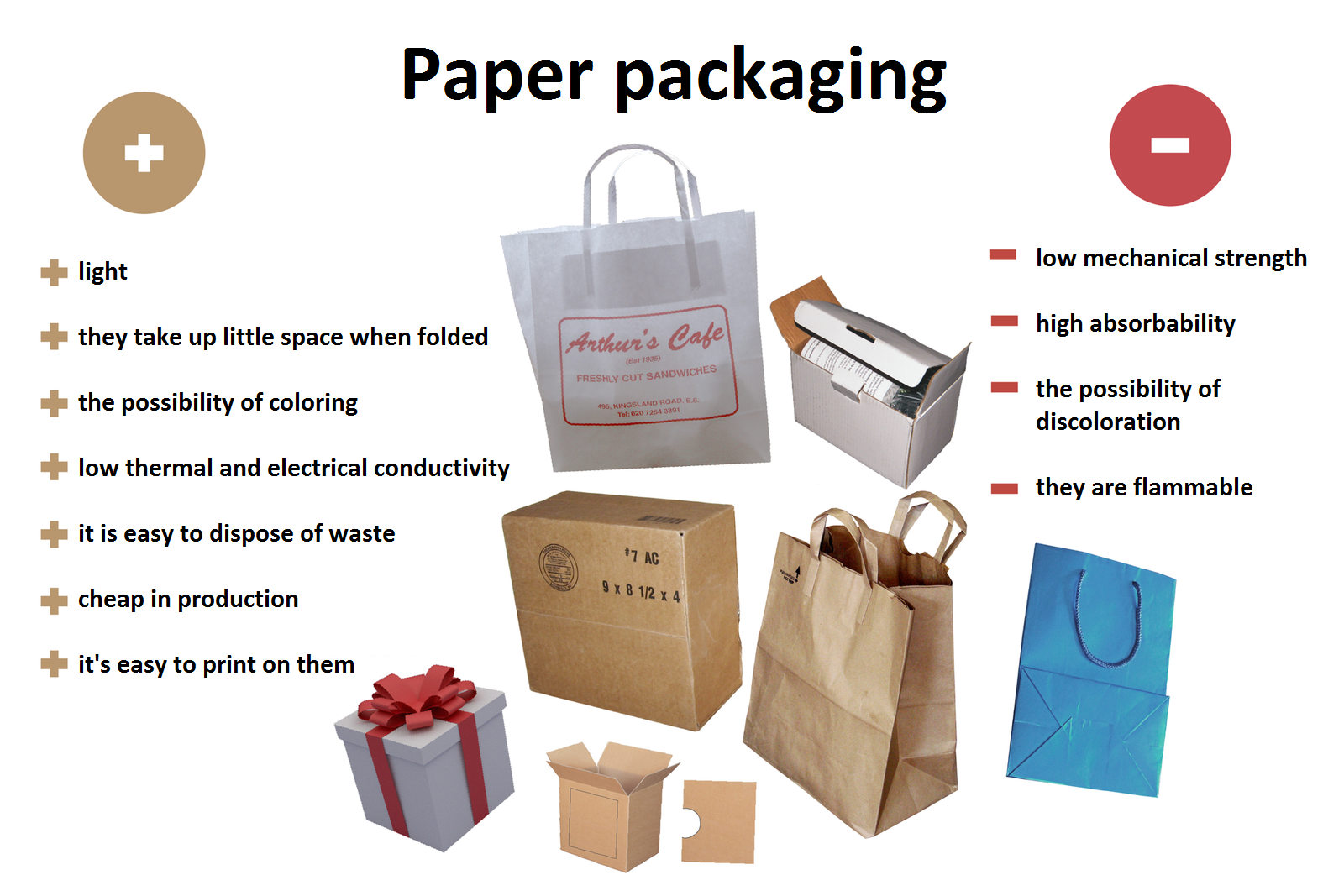

Paper packaging

Paper is a brilliant material invented in China at the beginning of our era. It is mainly produces from cellulose – the most important component of plants, which is a polysaccharid when its chemical structure is concerned. It consists of the rests of glucose molecules () linked to each other with glycosidic bonds in long, unbranched chains.

Acids are chemical compounds that destroy glycosidic bonds. Cellulose is a solid, white, fibrous substance that is tasteless and odourless. It is neither soluble in water nor in organic solvent. It is flammable. Most cellulose can be found in fibres of cotton, flax, hemp, jute – even more than 90% – and wood – about 45–50% (mass percentage). Quality and durability of paper depend on raw materials used to manufacture it and production technology.

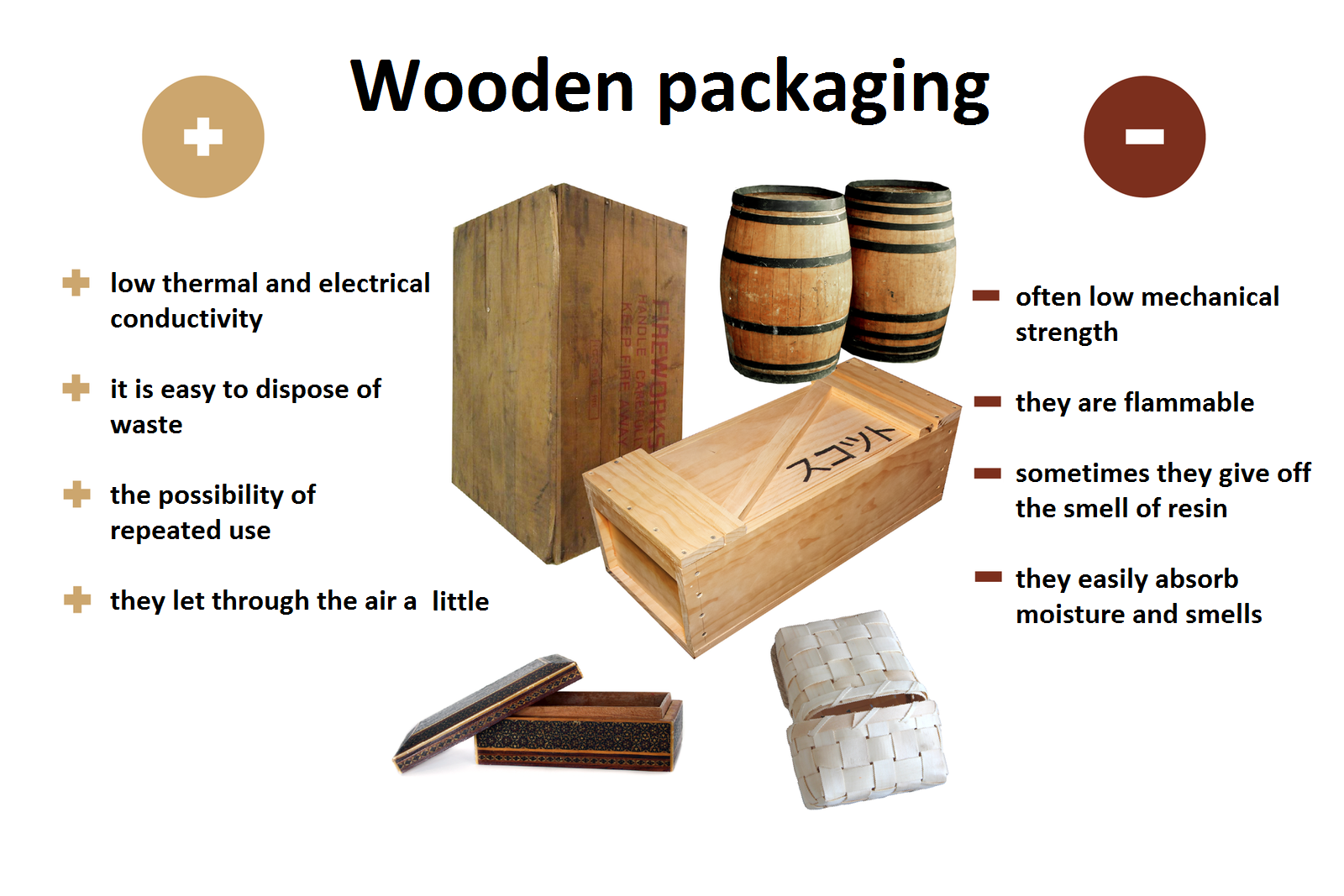

Wooden packaging

Wooden packaging have been used for ages, mainly to sell agricultural products and store food. Such packaging should not be produced from wood obtained from trees with large quantities of resin. Furthermore, tree species has impact on the type of stored goods, for example oak or beechmast wood is used to ferment cabbage and cucumbers, larch wood is used to store vinegar, wine can be stored in oak or acacia barrels, while salted herring is stored in spruce barrels. Wooden packaging even more often have a decorative function. Moreover they are used as bulk and transport packaging. Nowadays wood is replaced with other materials as it is difficult to keep such packaging clean, it requires frequent renovation, is expensive and their production involves cutting down trees.

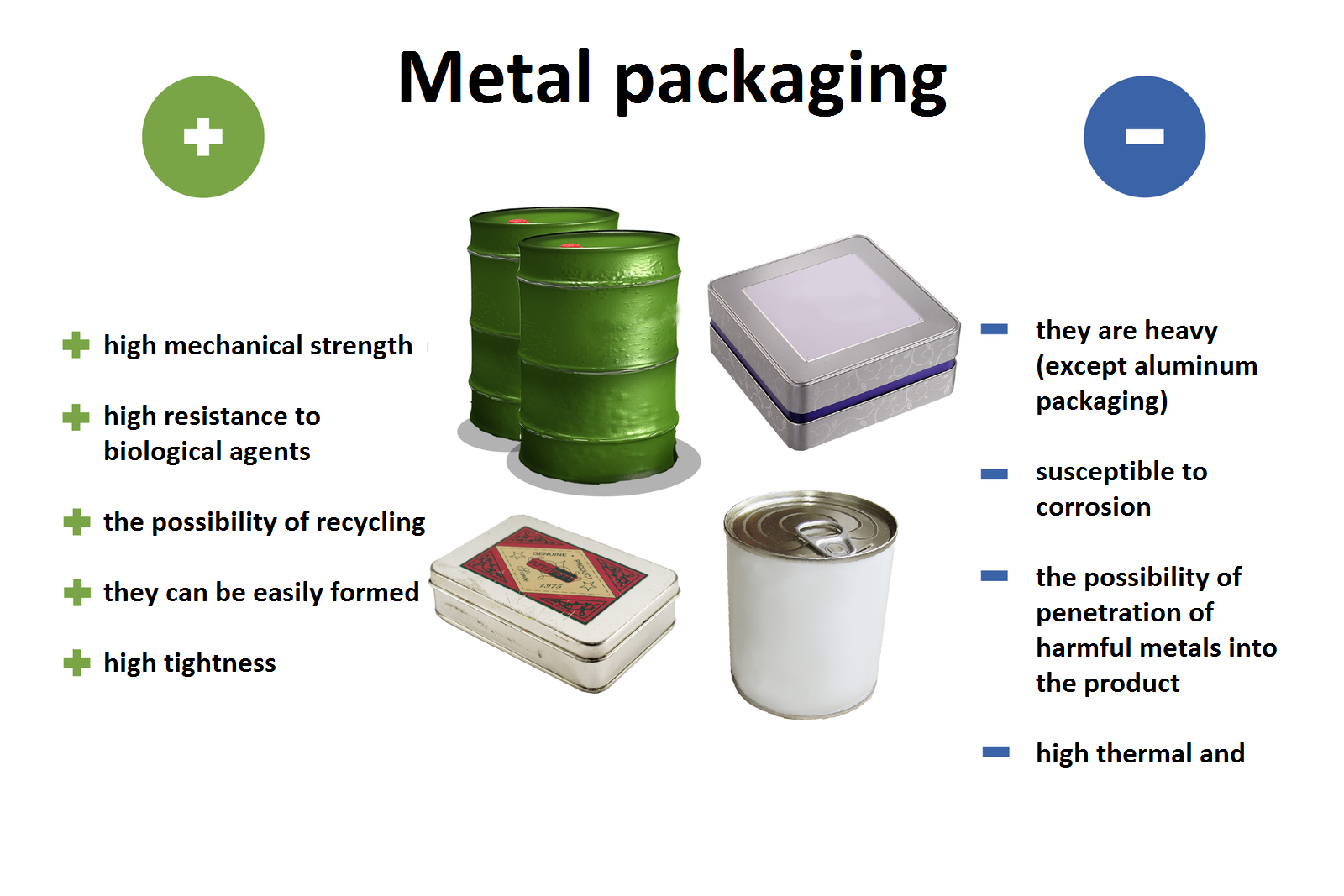

Metal packaging

Metal packaging is used to store food products that need to be hermetically sealed, for example canned meat or fish, preserved vegetables and fruits. Apart from canned food, you can also buy other goods, such as paints, varnishes, cosmetics, plant protection products, liquefied gases, etc. Galvanized steel sheet and aluminium are mainly used to produce metal packaging to store food. Other articles can be stored in containers made of bluesteel sheet, or galvanized, chromed or nickel‑plated steel sheet. As undesired chemical reactions make occur between metal and food product, a sheet is coated with tin or acrylic lacquer. Currently, cans with beverages, mainly carbonated drinks, are the most typical metal packaging on the market.

Packaging made of fabric

Fabrics are one of the oldest packaging types. Fibres of cotton, linen, jute and hemp are made of cellulose – like paper. Cellulose sacks can be used to store and transport cereals, coffee, vegetables, fruits, and seeds. It is the best packaging for bulk goods, which should have air access. Although their weight is low, they are biodegradable and can be repeatedly used, they are increasingly more often replaced with packaging made of synthetic fibres, mainly polyamide and polyester ones, and of plastics.

Packaging made of plastics

Plastics, the so‑called polymeric materials, are macromolecular compounds. One of the ways to obtain them is as a result of polymerisationpolymerisation which involves many molecules of unsaturated compounds (monomers) being combined into one large molecule (polymer), by breaking multiple bonds.

Polyethylene, especially the one of high density, is used in the production of food packaging. It is reusable and considered to be the safest packaging material.

PET is a material resistant to acids and some organic solvents. It exhibits high mechanical strength. Bottles made of this material that are used to store beverages and vegetable fats are most often encountered on the market. Modern packaging, for example the ones to be used in microwave ovens, is made of rigid PET film and covered with a thin crystalline layer of this material, giving it resistance to high temperature and excellent transparency.

Formulate a research question and hypothesis before watching a video “How to differentiate PE from PET”. Write down your observations and conclusions.

Film dostępny na portalu epodreczniki.pl

Film pokazujący eksperymenty które pozwolą nam odróżniać PE od PET. Na stole leżą zlewki z wodą, water, podstawka z poli(tereftalanem etylenu), polyethylene terephthalate, podstawka z polietylenem, polyethene i penseta, pincette. Do zlewek wrzucane są kawałki substancji z podstawek, polyethylene terephthalate tonie w wodzie, natomiast polyethene unosi się na powierzchni. Następuje druga część eksperymentu. Ustawione jest 8 zlewek z różnymi płynami w środku. Do każdej pary zlewek jest wlany jeden płyn. Pozwala nam to odróżnić PE od PET. Następny eksperyment polega na dostawianiu kawałka materiału do ognia. Materiał PE w płomieniu palnika spala się i topi po wyciągnięciu z płomienia. Materiał PET reaguje kurczeniem tylko podczas trzymania nad płomieniem.

Comparison of selected physical and chemical properties of polyethylene and polyethylene terephthalate.

PE and PET are plastics that show some similarities and differences as far as their physical and chemical properties are concerned.

2 beakers with cold water,

2 test tubes with acetone,

2 test tubes with tetrachloroethane,

2 test tubes with concentrated solution,

2 test tubes with concentrated solution,

a PE sample,

a PET sample,

metal pliers,

burner,

watch glass.

Check density of PE and PET in relation to water by placing tested samples in beakers with water.

Observe what is going on with the samples placed in acetone, tetrachloroethane and concentrated and solutions.

Using metal pliers, place each sample in the flame and put the watch glass under each sample. Check if the samples are also burning after being removed from the flame.

Other packaging types

Nowadays both producer and consumers place high demands on packaging. That is the reason why the market is still surprising us with interesting solutions that make life easier. Progress mainly concerns food packaging, which contradict solutions used so far, namely eliminating interactions between food and container.

Active packaging create a system of elements interacting with each other with the product and its vicinity. In case of food it extends its expiry date. Intelligent packaging enables control of product’s safety during storage, informing the consumer about this fact.

Multilayer packaging consists of numerous components and are produced by combining at least two various materials. Most often paper is combined with metal (the first one ensures adequate rigidity and strengthens the structure of the packaging, while the latter one protects the product against light and oxygen) and plastic (PE ensures tightness and protects the packaging and its contents from moisture). Milk, fruit or vegetable juice, sauce, soup containers are the examples of such packaging.

Requirements related to environmental protection and the high cost of recycling of a large number of packaging waste have led producers to manufacture biodegradable packaging, namely those that are decomposed under the influence of microorganisms. Traditional plastics are most frequently modified using starch or cellulose. Such packaging can be composed together with organic waste.

At least how many layers are there in multilayer packaging?

- one

- two

- three

- four

PET packaging:

- is only resistant to acids.

- is only resistant to some organic solvents.

- is resistant to acids and some organic solvents.

- cannot be used to store acids and organic solvents.

Summary

Packaging is an important component of the product. It should ensure adequate protection, enable storage of goods, their transport, sale and consumption quality.

The materials from which the packaging is produced are selected taking into account the following factors: possible interaction with the product, resistance to external conditions, material and packaging costs, and the impact on the natural environment.

As far as material type is concerned packaging can be divided into: the one made of glass, metal, cellulose, plastics and multilayer.

The following examples of polymerization materials can be given: polyethylene, polypropylene, polystyrene, polyvinyl chloride, polymethyl methacrylate.

Polyethylene terephthalate is an example of a polycondensation material.

As economic standards are changing, new materials and technologies used to produce packaging are constantly sought for.

A 0.5 litre glass bottle was filled with a 10% acetic acid solution with a density of 1.05 g/cmIndeks górny 33. Calculate how many grams of this acid are in solution (vinegar) stored in this bottle.

Keywords

packaging, plastics, polymerisation reaction

Glossary

opakowanie – element produktu chroniący go przed działaniem czynników zewnętrznych, umożliwiający i ułatwiający jego transport, magazynowanie, sprzedaż, zawierający określone informacje i znaki kodowe

polimery – substancje wielkocząsteczkowe składające się z wielu powtarzających się jednostek zwanych merami; mer to najmniejszy, powtarzający się fragment łańcucha polimerowego

reakcja polimeryzacji – proces łączenia się wielu cząsteczek związków nienasyconych (tzw. monomerów) w dużą cząsteczkę (tzw. polimer), kosztem pękania wiązań wielokrotnych

tworzywa sztuczne – materiały, których głównym składnikiem są makrocząsteczki; są wytwarzane z surowców naturalnych przez ich częściową modyfikację

polikondensacja – reakcja polimeryzacji, przebiegająca stopniowo i z wydzieleniem niskocząsteczkowego produktu ubocznego (np. wody, metanolu, glikolu)